Products

Product

It reduces the price and weight

Best materials to maintain

performance

product

description

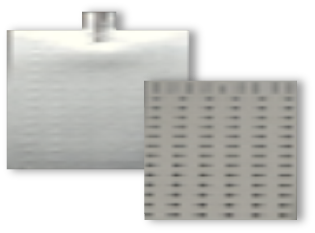

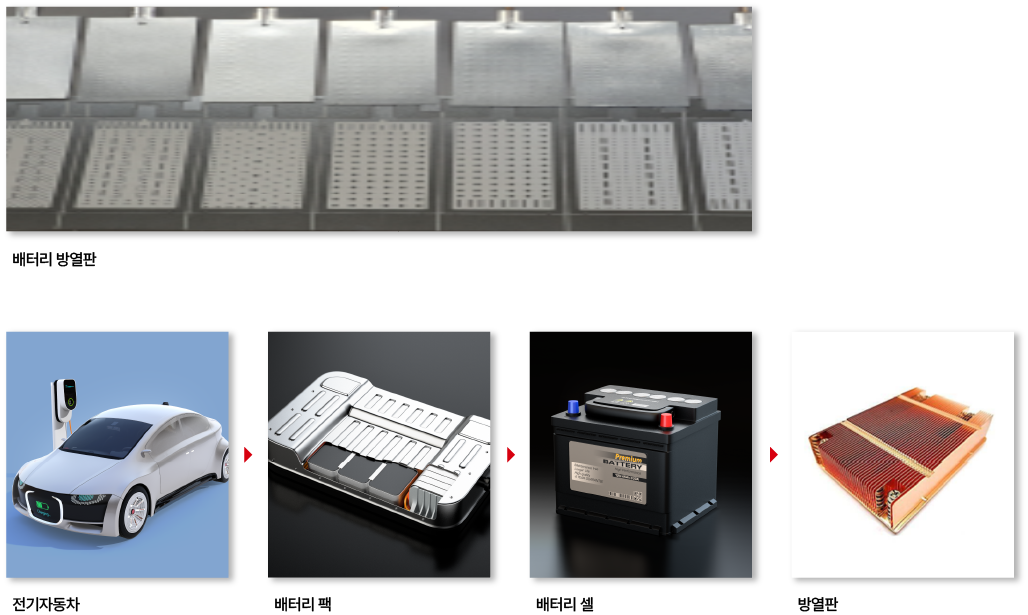

Battery heat sink: Vapor chamber

As the demand for electric vehicles continues to increase, accidents such as fires and reduced battery

life are occurring due to internal heat, which is one of the causes of secondary battery accidents.

To solve this problem, automakers are actively conducting research on secondary battery heat dissipation

systems.

In particular, many studies are being conducted because the Vapor Chamber, a battery heat

sink,

maintains a constant pressure in a closed space in a vacuum state, rapidly diffuses contact

heat inside and discharges it to the outside.

development

Korea’s only lead tab film localization and manufacturing success

Japanese companies occupy more than 90% of the global lead tab film market.

Under these circumstances, Best Energy is the only company that specializes in manufacturing lead tab

films in Korea. Best Energy has succeeded in developing lead tab films for secondary batteries through

many years of polymer research.

In particular, we contributed to the localization of secondary battery materials by using all raw

materials used to manufacture them only domestically.

The lead tab film manufactured in this way has been tested in the safety field by China's top three

secondary battery manufacturers for 6 months and its performance has been recognized.

product

FEATURES

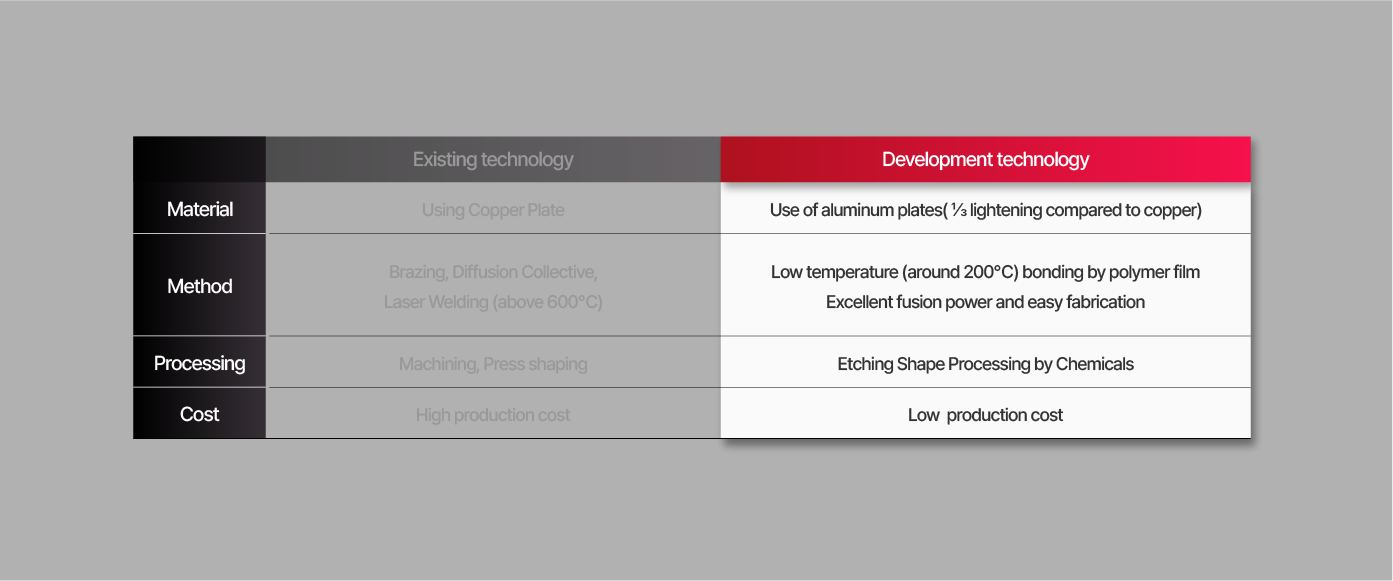

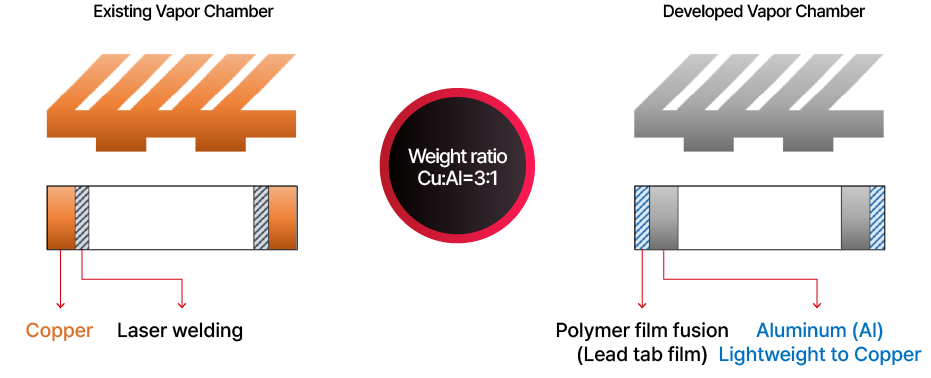

Need for Aluminum Vapor Chamber

Vapor chambers are currently manufactured based on copper (Cu). However, the high price of copper, yield

problem due to brazing method (about 80%), and heavy weight are considered problems. Best energy is to

solve this problem with aluminum (Al)-based vapor chambers, not copper-based ones.

Aluminum costs only 30% compared to copper and its specific gravity is also ⅓ compared to copper, making

it the best material to maintain performance while reducing price and weight.