Products

Product

Materials that prevent battery

explosion and maintain battery

stability

product

description

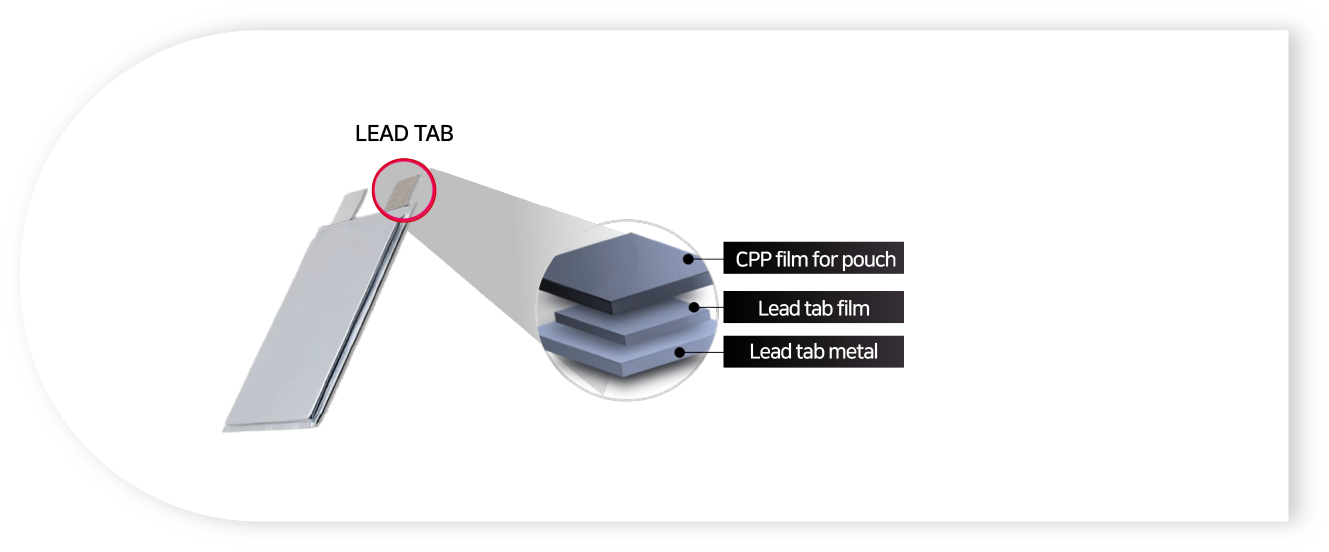

Secondary batteries (battery) used in electric vehicles are divided into three types: square, pouch,

and cylindrical. Here, a pouch-type secondary battery consists of a positive electrode, a negative

electrode, an electrolyte, and a pouch film and lead tab, which are packaging materials. The lead

tab serves to connect the negative and positive plates of the secondary battery to the outside by

electric power. It is the lead tab film that seals the lead tab and the pouch film, which is a

packaging material.

A cell generates heat and pressure inside while an electric current flows. This generates

hydrofluoric acid (HF) gas, and there is a risk of battery explosion in case of damage to the

packaging. The lead tab film is an essential material to prevent the risk of battery explosion and

maintain battery stability.

development

Korea’s only lead tab film localization and manufacturing success

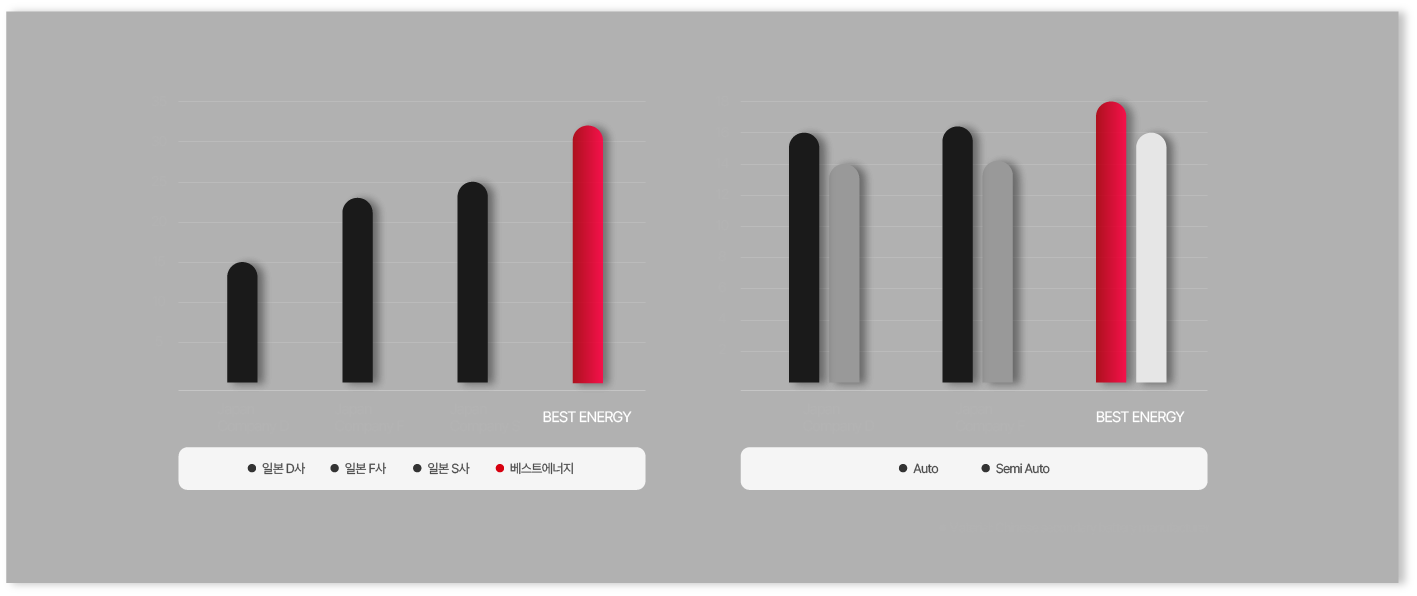

Japanese companies occupy more than 90% of the global lead tab film market.

Under these circumstances, Best Energy is the only company that specializes in manufacturing lead tab

films in Korea. Best Energy has succeeded in developing lead tab films for secondary batteries through

many years of polymer research.

In particular, we contributed to the localization of secondary battery materials by using all raw

materials used to manufacture them only domestically.

The lead tab film manufactured in this way has been tested in the safety field by China's top three

secondary battery manufacturers for 6 months and its performance has been recognized.

product test

Peeling Test, AI

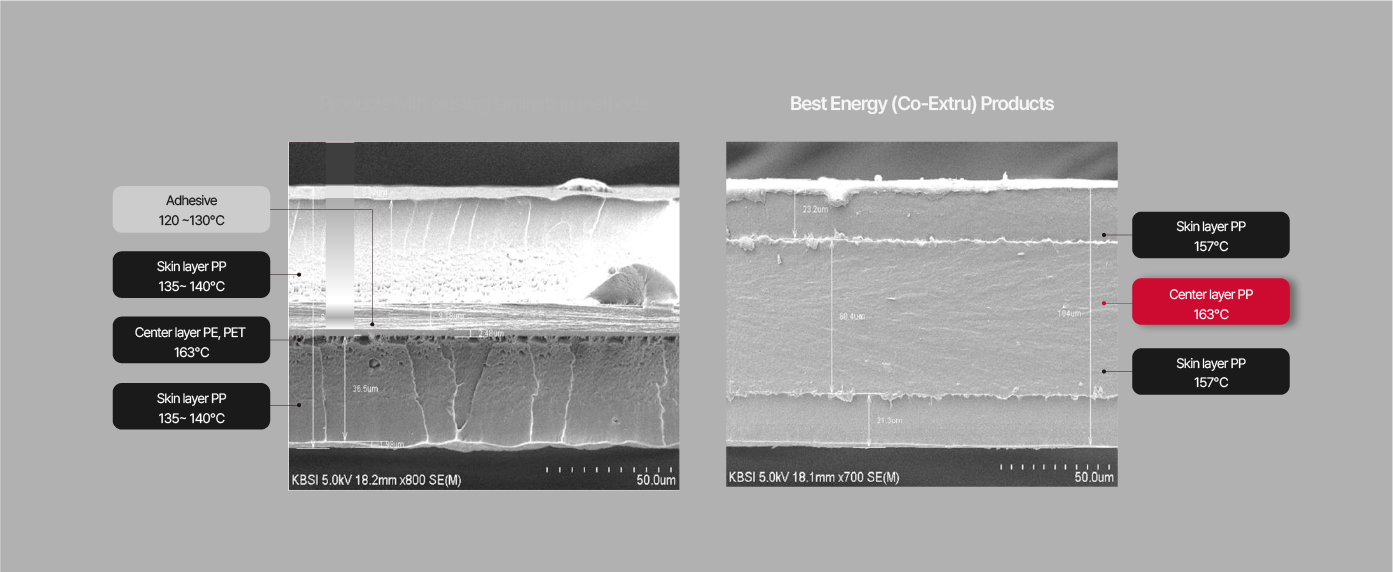

The best energy lead-tab film is not a laminating method that combines different materials, but from the

extrusion stage

It adopts the Co-Extru method that separates three layers.

The film, which is divided into a skin layer and a center layer, is all made of the same polypropylene

material.

Unlike the laminating method that combines polypropylene with other plastic materials such as PET, the

Co-Extru method is by electrolyte

It is more suitable for packaging and sealing secondary batteries as there is no separation between

species.